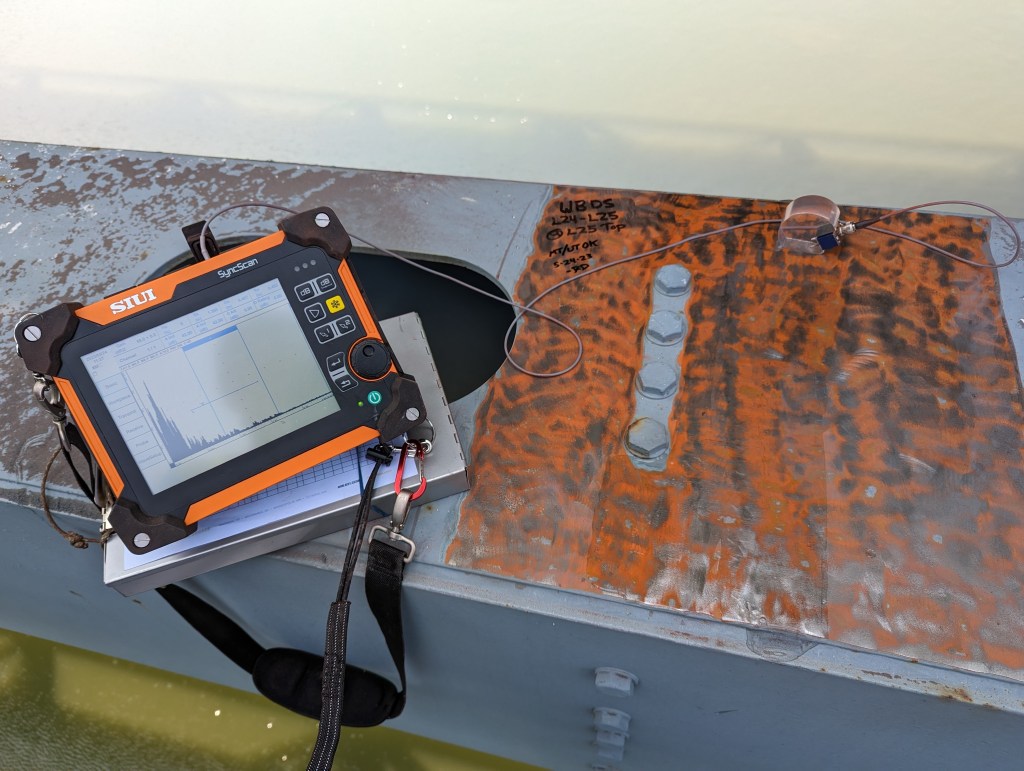

Ultrasonic Testing (UT) uses an instrument that generates a high frequency beam of sound to detect, characterize, and accurately size subsurface discontinuities.

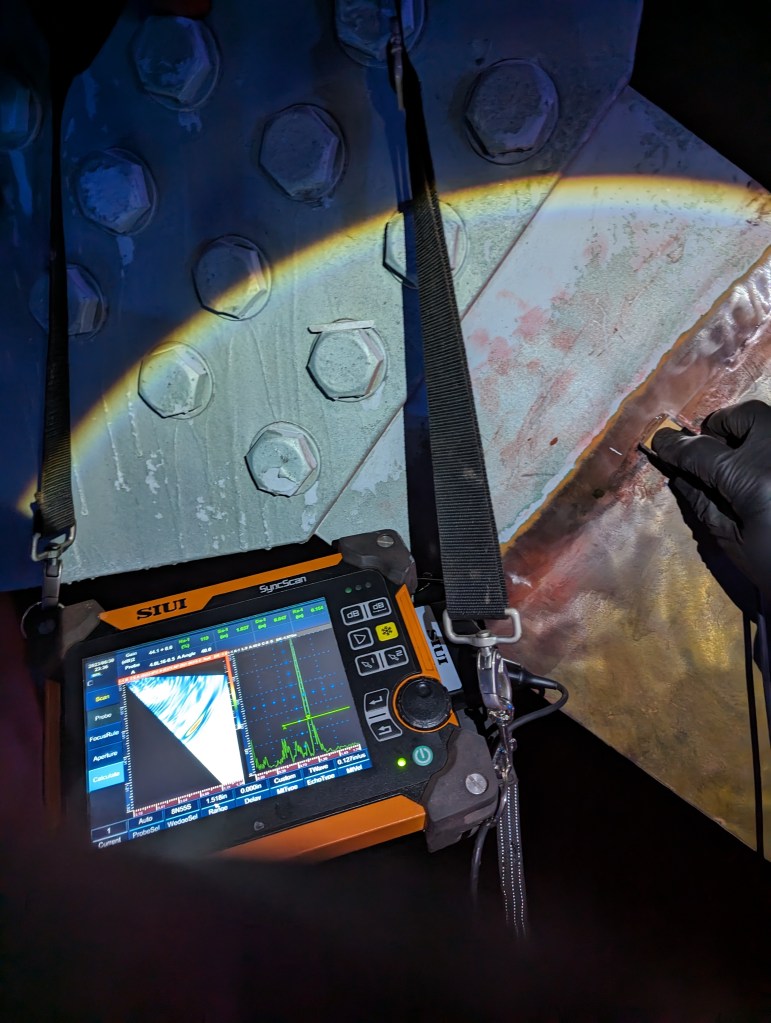

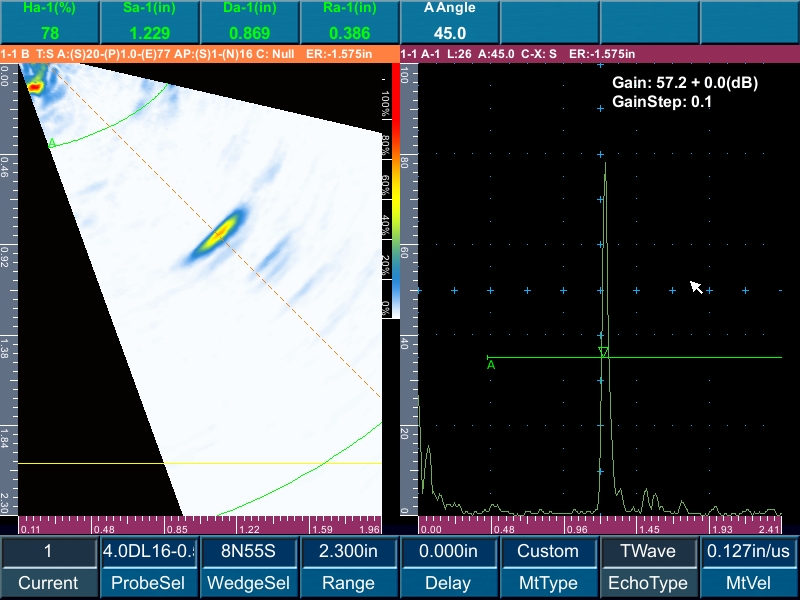

A phased array probe is made up of multi-element ultrasonic transducers. Using this technique the ultrasonic beam can be focused to a specific angle distance inside the examined object. The inspection data can then be saved so it can be compared for future reference and inspections.

Ultrasound can be used on a wide variety of materials. It is a highly sensitive test that can be used to detect cracks, lack of fusion, laminations, porosity, inclusions, voids and geometric conditions. It can also be used to measure the thickness of a material with an accuracy of .001”. A common application of ultrasonic thickness measurement is to monitor corrosion and erosion of pipes and vessel walls.

North Star Inspection can meet your testing and documenting needs using the industry standards you require.

Our modern UT instruments are enabled for signal processing, precise measuring and flaw evaluation to an acceptance criteria using updated documentation software.

North Star Inspection specializes in the use of phased array UT technology useful to the oil and gas, power generation industries as well as construction of new piping, pipelines, vessels, raw materials, machined parts, structural welded members and a variety of components providing excellent Quality Assurance. When quick and accurate inspections data is needed due to time constraints during outages this is a proven technique.

Applications for phased array:

- Weld inspection

- Volumetric inspection of forging or casting materials

- Erosion and corrosion mapping

- Scanning highly complex geometry components

Phased array has several advantages in comparison to other non-destructive techniques. It allows for faster examinations compared to manual ultrasonic testing. Information can be displayed in multiple display formats (for example, A, B, C and D scans), which help in more accurate interpretation of flaws. A further benefit of phased array is safety. There is no radiation or environmental hazards compared to radiography. With phased array there is no need to shut down operations due to radiation exposure so there is less wasted man hours and increased production.

You must be logged in to post a comment.